Definition: Supply chain management refers to controlling the flow of raw material, product, inventory, cash and information right from the place of origin to the final consumption of the product. A supply chain involves all the activities which an organization performs for consumer satisfaction. It includes product development, finance, marketing channel, transportation, customer service and other business operations.

A business comprises of various activities, people, department, associates and most importantly, it involves a risk factor.

If an organization is merely planning to produce some goods without knowing how it would procure the raw material, machinery and other resources, it may not be able to start even.

Content: Supply Chain Management

Example of Supply Chain Management

Let us take the case of a garment manufacturing unit.

A garment manufacturer plans a systematic supply chain management. He first plans for the machinery, i.e. dye machine, embroidery machine, stitching machine, etc.; raw material; i.e. fabric, threads, buttons, etc.; and other resources like packaging material.

The manufacturer then decides the relevant suppliers for acquiring the resources. Next, the production process is determined, where the flow of fabric, thread and buttons, as well as finished and packaged garments, is regulated in and out of the factory. For this movement, the transportation and distribution channels are planned.

The manufacturer takes orders from the garment wholesalers and retailers, and the order processing is done, which involves sorting and packaging. The order is then dispatched through the trucks to the desired destination. Simultaneously, the wholesaler transfers the payment directly in the manufacturer’s account.

While unloading the packages, the wholesaler finds out a damaged lot and informs the manufacturer. The manufacturer facilitates the return of the damaged lot of garments and transfers the refund for that particular lot directly in the wholesaler’s account.

The manufacturer communicates with the salespersons, wholesalers and retailers to know the customer needs and feedback for their products.

Process of Supply Chain Management

Supply chain management is a step by step process which remains as a standard for all the business operations. Let us now learn about these steps in detail below:

- Plan: The initial stage in the process of supply chain management is to develop a plan constituting the various strategies related to the procurement of raw material, manufacturing of goods, distribution of products, inventory management and warehousing, arranging for finance and customer handling.

- Source: This step deals with the decisions regarding the suppliers of the raw material. The supply chain manager is responsible for maintaining a cordial relationship with the suppliers to ensure continuous availability of raw material at a reasonable price.

- Make: In this stage, the whole concentration is on the manufacturing of the product. It involves product design, the method of production, product testing and sampling, packaging, etc.

- Deliver: In this step, the organization plans for the delivery of the manufactured goods to fulfil the orders. It includes distribution channel management, invoicing, receiving payments, warehousing and inventory management.

- Return: Customer service is the essential step where the companies need to arrange for the replacement or refunds in exchange for the products returned being either damage, dissatisfaction or defective. It includes pick up service, customer helpline, handling of queries and complaints, etc.

Supply Chain Management Activities

You must be wondering what all activities are performed under supply chain management? Why are they so essential for the organization? To understand the impact of supply chain management on the various departments of an organization, we must go through the following activities:

Customer Relationship Management: The companies are engaged in building customer loyalty toward the brand through customer relationship management. It involves identifying the customer’s need, designing the products accordingly and maintaining a customer database.

Customer Service Management: Supply chain management continuously focus on customer service and satisfaction through proper flow of information, addressing customer issues and working on feedbacks.

Supplier Relationship Management: Communicating with the suppliers and enhancing public relations is essential for the regular supply of raw material and uninterrupted trade practices.

Manufacturing Flow Management: It includes all the operations which facilitate a transfer of raw material into the factory and transfer of finished goods out of the factory. It ensures a flexible and systematic manufacturing process to produce products or services at the lowest possible cost.

Demand Management: Demand forecasting and analysis are necessary to meet the needs of the customers in the best possible way. It is also provided for the preparation of the sales budget and supply estimation.

Order Fulfilment: Supply chain management includes activities related to order processing and fulfilment like handling queries, taking up orders, order delivery, coordinating with the customers and the suppliers, etc.

Product Development and Commercialization: The company needs to be updated with the ongoing trend, and the customer wants. This is essential to survive in the long run by making the required changes in the product or develop a new product through innovation.

Returns Management: Reverse logistics is the flow of goods from the customers back to the company due to specific issues like damage or defect. It is a must needed activity for the company to gain customer loyalty and satisfaction by working on the loopholes.

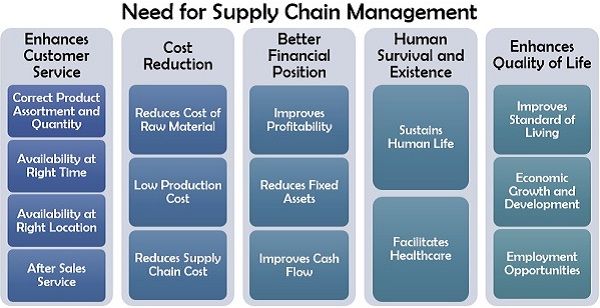

Need for Supply Chain Management

The regulation and movement of information, goods and money in business are necessary for the proper functioning of all the departments and achievement of organizational goals. It is also essential for the economy and growth of a nation.

Let us see why supply chain management has gained so much importance, for any business as well as for the country:

Enhances Customer Service

A business revolves around its customers, and consumer satisfaction is the critical factor of all business activities. To ensure proper customer service, supply chain management is needed.

The customer seeks for the right product, in the correct proposition and the right quantity, on-time delivery of the products, availability of the product at the accessible location and prompt after-sales service.

Cost Reduction

Supply chain management streamlines the business process by reducing the overall cost incurred on the procurement of raw material, manufacturing of goods and expenditure incurred on supply chain management.

Supply chain management ensures acquiring the raw material from the suppliers at the lowest possible price as well as looking for better deals.

It provides for the regular supply of materials and tools to the manufacturing and assembling units to avoid loss from the temporary shutdown of production units.

Supply chain cost, i.e. the cost of maintaining a large inventory and obsolete products can be reduced by enhancing sales and better customer service.

Better Financial Position

Financial viability and management is an essential factor in organizational growth. A proper supply chain management controls the expenses of the company to improve its financial health. When the sales are in bulk, a slight cost-cutting in the supply chain can lead to a remarkable difference in the profitability.

Supply chain management is all about building up of networks taking the help of the tertiary sector to reduce the cost of fixed assets. The faster the product reaches its customer; the sooner is the payment made. This reduces the debtors and improves the cash flow of the company.

Human Survival and Existence

Supply chain management is necessary to move the goods or services from its point of origin to its end-user. In the direction of humanity and to protect human life, supply chain management is required at the time of crisis to move the resources from one place to another.

It also acts as a saviour at the time of medical emergencies and rescues like the hospital’s supply chain management.

Enhances Quality of Life

Usually developed countries have a better standard of living due to a well-structured supply chain. It also improves the transportation system, communication system, infrastructure, etc.

It enhances profitability from the trading and business activities to ensure economic growth and development of a country.

Better supply chain means more business and more business means more employment opportunities.

Conclusion

The companies require a full proof plan of; what they want to produce? Where will the raw material come from? How will the goods move in and out of the plant? How much capital is required for moving the goods? How will the products reach their customers? And so on.

The answer to all such questions is a well planned and organized supply chain management.

Leave a Reply