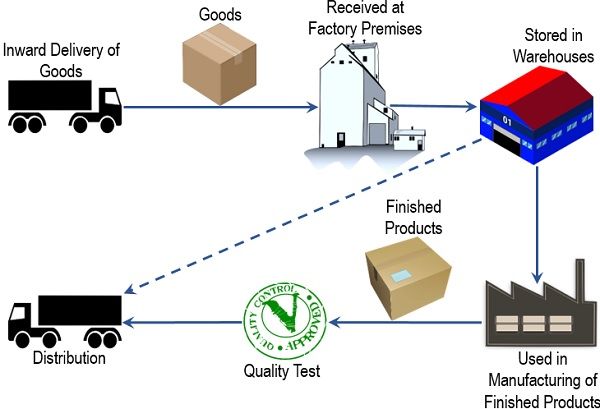

Definition: Inventory management is an approach for keeping track of the flow of inventory. It starts right from the procurement of goods and its warehousing and continues to the outflow of the raw material or stock to reach the manufacturing units or to the market, respectively. The process can be carried out manually or by using an automated system.

When the goods arrive at the premises, inventory management ensures receiving, counting, sorting, arrangement, storage and maintenance of these items, i.e. stock, raw material, components, tools, etc., efficiently.

To see how this whole system functions, we should first understand the flow of inventory in an organization. The same has been represented in the following diagram:

Here, the goods which are stored in the warehouse can be utilized in the following two ways:

- Direct distribution in the market i.e., to the wholesalers, dealers, retailers or customer; or

- Sent to the production units for manufacturing of finished goods.

There are many inventory management techniques available for organizations to choose from. Some of the most common ones are EOQ (economic order quantity), ABC analysis, just-in-time management, EQR model, VED analysis, LIFO (last in last out) and FIFO (first in first out).

Content: Inventory Management

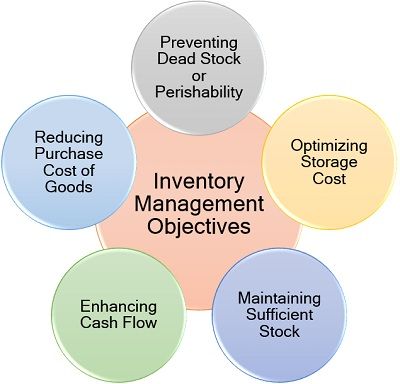

Inventory Management Objectives

Inventory management is performed to simplify the operational activities. Some of the primary objectives for which it is carried out are as follows:

- Preventing Dead Stock or Perishability: With an optimal inventory level, the chances of wastage in the form of goods spoilage or dead stock.

- Optimizing Storage Cost: It reduces the chances of maintaining excessive stock, even the requirements are pre-determined, which ultimately cuts done the unnecessary warehousing costs.

- Maintaining Sufficient Stock: Now, the production department need not worry about the shortage of raw material or goods because of its constant supply.

- Enhancing Cash Flow: Inventory has a significant impact on the cash flow of the company. With effective inventory management, the organization can ensure sufficient liquid cash to enhance its operational efficiency.

- Reducing the Inventories’ Cost Value: When there is a constant purchase of goods or stock, the organization can ask for discounts and other benefits to decrease the purchase price.

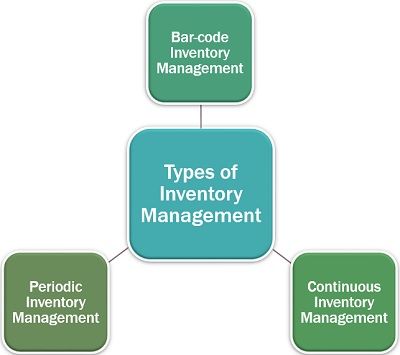

Types of Inventory Management

While installing an inventory management system, the organization has to consider the various aspects like cost, budget, utility and accessibility. However, it can be classified into the following types:

Bar-code Inventory Management

The barcode system is its automated and simplified version. The management can find out the stock remaining with just one click on a computer device. The scanned barcodes enable the software to maintain a track of all the purchases and the flow of inventory.

Continuous Inventory Management

It links the barcode and radio frequency identification with the accounting inventory system, inventory received, and point of sales systems along with the production system, to trace the path of inventory movement. It is mostly beneficial for accounting purpose. This is also termed as perpetual inventory management.

Periodic Inventory Management

It is a manual process, which is used for determining the closing inventory value, for putting it up in the ledger at the end of a financial year. Depending on the organizational need, it can also be analyzed quarterly. However, it is a time-consuming way, since the inventory has to be physically counted.

Inventory Management Process

Since it is a process of identifying and resolving inventory-related obstacles. Given below is the step by step method of improving the organization’s inventory management system:

Step 1: Determining the Loopholes

The foremost step is to evaluate the inventory requirement and the actual stock of the goods. Also, the reasons for this gap between the demand and inventory should be ascertained.

Step 2: Analyzing Consumer Demand and Spending Patterns

The market demand forecasting holds equal importance. This is because it helps the organization to estimate the production quantity, which ultimately leads to the maintenance of adequate inventory.

Step 3: Evaluating the Cost Involved

Its implementation involves different types of expenses such as warehousing, maintenance, transport, bulk discounts and supply chain costs. Each of these should be well analyzed.

Step 4: Identifying the Extent of Process Automation

It is not possible for every organization to completely automate the inventory management process. However, the management can recognize those particular areas where there are possibilities of automation.

Step 5: Inspecting Supplier’s Practices and Performance

The next step is to find out the suppliers’ inventory management practices since this strategy cannot be implemented solely. If the supplier is resistant to change and tends to proceed with the traditional means, the organization needs to look for alternative vendors.

Step 6: Classifying Inventories into Different Categories

The goods have to be segregated into various categories depending upon the product type, customer class, maintenance cost or profit margin.

Step 7: Setting Objectives for Each Inventory Category

To efficiently manage and track the performance of the applied technique for each category, it is essential to set individual goals. It not only provides a base for benchmarking but also identifies the problems and issues faced in each of these categories.

Step 8: Prioritizing the Areas of Improvement

Now, that we are aware of the problems, the next step is about finding out the density of each issue and its impact. The concerns which can be resolved immediately needs to be addressed first. And then, the ones which are complex and requires restoration should be considered.

Step 9: Taking Advice or Opinion from Experts

Designing an appropriate inventory management system is the task of the personnel who specialize in the field. Thus, at this stage, the organization needs to hire consultants or experts for advice and opinion on current technology and problem fixation within the desired budget.

Step 10: Framing Suitable Inventory Management Policy

The last step is to implement a satisfactory inventory management strategy for the desired change. This improvement should be incorporated as an inventory management policy to deal with the changes in demand and add value to customer experience.

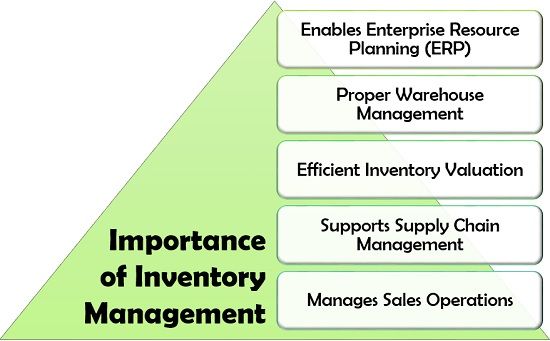

Importance of Inventory Management

The evolving technology and changing consumer preference have significantly brought forward the need for a robust inventory management system. Given below are some of the most prominent reason for which it is considered beneficial for every business entity:

Enables Enterprise Resource Planning (ERP)

The ERP software accommodates and links the different business operations. These are inventory procurement, warehousing, production, human resource, finance, marketing and sales to one another. In this process, inventory management contributes its part of providing the necessary data.

Proper Warehouse Management

The barcode system, LIFO and FIFO techniques provide a clear picture of the past and present inventory available with the company to optimize the warehousing functions.

Efficient Inventory Valuation

It provides for proper evaluation of the different types of inventory, i.e., stock in hand, opening and closing stocks, raw material, finished goods, etc. This data is also used to prepare the cost sheet.

Supports Supply Chain Management

Being a segment of supply chain management, it is responsible for streamlining all the warehousing operations and flow of raw material or stock.

Manages Sales Operations

Sales, as we know, is a continuous process which depends upon the production of goods or services. If there is inefficient inventory management in the organization, the chances of unavailability of raw material for manufacturing may arise.

Challenges Faced in Inventory Management

Inventory management has become an inevitable part of significant business entities. Also, many small organizations have adopted the concept to keep track of their stock and raw material.

But while practically implementing it, the companies have to deal with the following limitations:

- Lack of Knowledge: The personnel at the receiving and warehousing departments may lack the required expertise and adequate knowledge of segregating the regular and seasonal goods out of the whole stock.

- Expanding Product Portfolios: The customers’ demand and requirements for a wide range of products have tremendously increased the inventory size, making it difficult to manage, manually.

- Supply Chain Complexity: The organization, at times, fail to track the stock or goods during the supply chain process. Moreover, it is not necessary that the business partners also maintain an inventory management system, creating hurdles.

Conclusion

Inventory management is a useful method for simplifying all the warehousing activities of the organization. With this technique, the company can now access and determine its stock and inventory with efficiency to smoothen all the business operations.

It has also proved to be a valuable tool for maintaining the working capital requirement.

sivaram says

Very Good Article

Gehanath Gautam says

very descriptive article . thank you

Abiodun Sanbe says

very interesting