Definition: The Material Requirements Planning or MRP is a subset of the Inventory Control System. It determines the exact quantity of dependent demand items required for production as specified in the Master Production Schedule (MPS).

Where Dependent Demand Items include components of the final product and its sub-assemblies. The information about these items is obtained from the items listed in the BOM & MPS.

Basically, it transforms the gross requirements of MPS into time-phrased net material requirements.

Note: It covers all inventory items except finished products or end items.

Firms can conduct MRP both manually and electronically over softwares. However, in practice, the manufacturers prefer softwares for requirements planning.

Also, it helps attain materials available at the right time and optimal cost. To achieve this objective, managers need to balance their Supply and Demand.

Besides, it facilitates: –

- Inventory Tracking

- Production Scheduling

- Manufacturing and Delivery

Thus, in simple words, we can understand it as a computer-based materials management technique. In addition, it portrays a clear picture regarding Orders – Releasing, Rescheduling and Cancelation.

Material Requirements Planning provides solutions for the following queries:

- What items are required?

- In what quantity are they required?

- When are they required?

To solve the above queries, MRP uses Forward and Backward Scheduling.

Content: Material Requirements Planning

- Objectives

- Components

- Requirements

- Process

- Inputs and Outputs for MRP

- Flow Chart

- Importance

- Challenges

- MRP II and Lot-sizing

- Example

- MRP vs ERP

- Conclusion

Objectives

Manufacturers conduct Material Requirements Planning with the following objectives:

- Material Availability: Through MRP, managers ensure the availability of the materials/sub-assembly items.

- Time and Delivery: It helps in identifying the time required to obtain and deliver the materials.

- Low Inventory: It aims to maintain the minimum level of Inventory.

- Planning: MRP’s prime objective is planning manufacturing-related activities of the unit.

- Scheduling: Another important aspect of MRP is scheduling. It helps optimize delivery schedules to deliver the right amount of Inventory when needed.

- Prioritize: It helps prioritise the material queue to arrange materials as and when required.

Components

Following are the components of the Material Requirements Planning system:

- Master Production Schedule (MPS)

- Economic Order Quantity (EOQ)

- Items Master File

- Bills of Materials (BOM)

- Inventory on-shelve

Requirements for Material Requirements Planning

The following information must be available before initiating the MRP process:

- The breakdown of the composition of the end product.

- The expected lead time of the materials at different processes.

- Schedule of demand and delivery of the end-products.

- Information about the current in-hand stock of the items.

Process

Now, let’s understand the generalized step-by-step process of conducting MRP.

Step 1: Estimation of Net Requirements to meet demand

The process begins with identifying the number of units required to meet the demand. Thereby disintegrating the end product into multiple individual items.

In addition, acquire the list of required materials from the BOM. And converting the gross requirements specified in MPS into net requirements.

Step 2: Evaluate existing Inventory against demand

After assessing the net requirement check, the existing Inventory against the demand received. For this purpose, you can use the following formula:

Total number of units needed – Available stock

After that, allocate necessary raw materials to the items as per the requirement.

Step 3: Scheduling Production

The next step is to schedule the production to produce the required quantity. It includes the allotment of the number of workers needed to carry out production. Also, it determines the time and date for the delivery of the demanded products.

MRP involves two-way scheduling, i.e. Forward or Backward Scheduling.

- Backwards scheduling:

It begins with ascertaining the on-shelf date of the product. And the scheduling takes place in the backward direction. - Forward Scheduling:

In this, scheduling is based on the starting date of the manufacturing process.

Step 4: Monitoring and Review

The last step is keeping track of the complete process. In addition, taking necessary corrective measures as and when required.

Inputs and Output for Material Requirements Planning

Inputs

MRP retrieve data from the sources given below. These sources are known as Inputs for MRP. However, the inputs are the same whether we conduct MRP manually or electronically.

- Master Production Schedule (MPS)

- Bills of Materials (BOM)

- Inventory Status

- Lead-Time data

- Lot-sizing Rule

Note: In the case of the software, the files containing the above information must be uploaded as Inputs.

Outputs

After processing the above inputs, MRP generates the following outputs:

- Work Order

- Procurement Notice

- Performance Reports

- About Costs

- Material Usage

- Lead-time Analysis

- Inventory Level and Forecasts

- Deviation from the Original Schedule

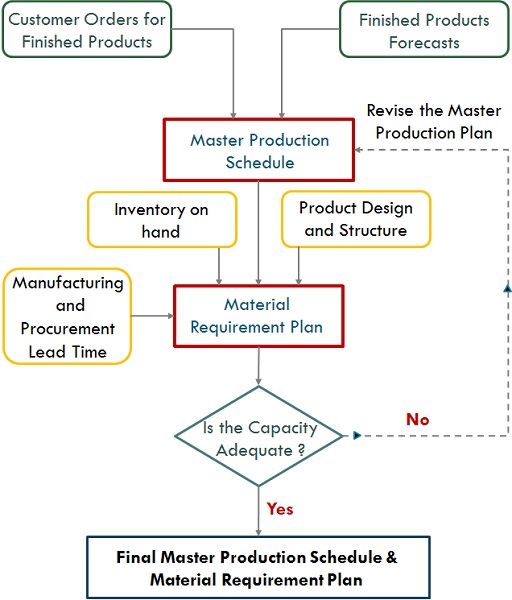

Material Requirement Planning Flow Chart

Importance

MRP is one of the essential techniques of Production & Operations Management. As it deals with the availability and on-time delivery of the right materials.

Besides, it benefits the manufacturing units in the following ways:

- It helps in minimizing the associated costs.

- Estimates and track the net material requirements in specific intervals.

- Facilitates the ascertainment of the EOQ and lot sizes.

- It is one of the key determinants of future capacity requirements.

- An active player in Inventory and Materials Management.

- Helps in accomplishing the delivery commitments previously made.

- Provides insights about the purchase and procurement of the materials.

Challenges

There are certain challenges or limitations that manufacturer faces when applying MRP. Some of these limitations are furnished below:

- The accuracy of results highly depends on the reliability of the inputs.

- It requires expertise to operate the MRP software.

- It is less flexible in nature. As it does not consider any uncertain capacity changes.

- The information about Lead time is provided manually, which can be inaccurate. In addition, the MRP software keeps it constant for all the materials.

- Processing time is considerably high as it deals with the massive volume of data.

- Based on the assumption that other processes are working as expected.

- The systems linked with MRP may not respond quickly.

- It excludes the capacity requirements, which are of concern during production.

- The software is complex and costly.

MRP II

MRP II is an abbreviation for Manufacturing Resource Planning II. We can call it an extension of Material Requirements Planning. The reason is that it has overcome the challenges faced by MRP.

In contrast to MRP, it also considers the facility’s capacity during resource planning.

Lot Sizing in MRP

Lot Size or Order Size is the total number of units produced in one go. It helps minimise the set-up and holding costs while ascertaining net requirements.

The lot-sizing method can either be based on Period or Quantity. Some methods for its determination are listed below:

- Economic Order Quantity (EOQ)

- Minimum Cost per Period (MCP)

- Period Order Quantity (POQ)

- Least Unit Cost (LUC)

Besides, there are specific rules for Lot-sizing as well:

- Fixed Period Requirements

- Lot for Lot

- Fixed Order Quantity

- Economic Lot Sizing

- Part Period Balancing

Example of Material Requirements Planning

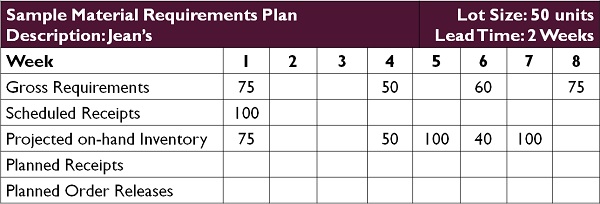

The table below depicts a sample MRP for Jean’s manufacturing unit.

It shows the requirement plan with a lead time of two weeks with a lot size of 50 units.

MRP vs ERP

| Basis | MRP | ERP |

|---|---|---|

| Meaning | MRP softwares helps to plan the requirements of the materials, components and sub-assemblies | ERP is software used to plan and manage day-to-day business activities. It is an extension of MRP |

| Objective | Plan and control production and assembly of goods | Planning for the organization as a whole |

| Scope | It has a limited scope as it only serves the production department | Whereas it covers the Marketing, Finance and Production Departments |

| Cost | In comparison, it is less costly | It is more expensive than MRP |

| Reach | A limited number of clients use it | It has a considerabilly large customer base |

Conclusion

To conclude, Material Requirements Planning is a software-based inventory management system. Also, it is a technique for achieving perfection in material procurement and delivery.

Manufacturers provide inputs to the MRP software to find out net requirements. Consequently, it generates ceratin outputs like work orders, Inventory level etc.

Leave a Reply