Definition: Make or Buy Decision is a tactical decision-making technique wherein the business concerns choose between – Inhouse Manufacturing and Subcontracting.

It is popularly known as the ‘Outsourcing Decision‘.

In the key phrase, ‘Make‘ signifies carrying out production within the firm. Whereas ‘Buy‘ refers to outsourcing the complete product or its components.

However, to arrive at a decision, firms conduct detailed evaluations referred to as Make or Buy Analysis. It is qualitative in nature and primarily based on the cost and benefits attached to it.

The firms can decide among three possible options:

- Outsource the complete product from the supplier.

- Manufacture the finished product and all its components internally.

- Manufacture some parts internally, and outsource the remaining parts. Subsequently, assemble all the components and make the final product.

These decisions are focused towards customer demand satisfaction. This is because firms aspire to gain profitability by satisfying the target customer’s demand. For this purpose, they either produce the product/service internally or procure it from external parties.

Almost all firms, whether big or small, face this dilemma at least once. But, there is no standard practice for all business concerns. This is because all the products and requirements differ among businesses.

However, conducting a cost and benefit analysis is mandatory. Besides, firms heading towards lean manufacturing prefer outsourcing over manufacturing.

The firm must select the alternative that maximizes profitability and reduces cost. In contrast, the wrong decision may adversely affect companies finances in the long term.

Content: Make or Buy Decision

Example of Make or Buy Decision

Suppose Z ltd., a bicycle manufacturing firm, is planning to launch a sports bicycle.

Top-level management is stuck in a dilemma to make this cycle in-house or subcontract it.

Now, let’s look at the cost facet of both alternatives.

Alternative: 1

Z ltd. can use the existing machinery for production with some additional raw materials. They can complete the overall production of 10 bicycles for $7000/-.

Alternative: 2

They can also purchase bicycle parts from external suppliers (industry experts). After assembling all the parts, the total cost of 10 bicycles is $7400/-.

Decision

Z ltd. decided to produce the sports bicycle in-house. The decision is based on the fact that the total cost of production is less than subcontracting.

Factors Affecting the Make or Buy Decision

In order to make a wise decision, firms need to examine several factors that affect decision-making. The most vital among these are Profit, Time and Accessibility.

Further, these factors are grouped under two broad categories given below:

- Costing Factors

- Cost: The cost incurred in purchasing or manufacturing the product is the first and essential factor in the decision process.

- Purchase Price: It specifically refers to the price paid by the firm to purchase the product or component. It plays a significant role in the decision process as it is one of the bases for comparison.

- Storage Cost: It refers to the cost incurred on storing the purchased products or components.

- Non-costing Factors

- Current Capacity: Another vital factor is the firm’s existing capacity. The manufacturer must analyze whether the existing capacity satisfies the demand or not.

- Finances: If the firm plans to subcontract the production, it must have the required finances to pay off the suppliers.

- Availability: Here, manufacturers concile the availability of resources with the quantity required.

- Expertise: Before manufacturing products internally, firms must check the skills and expertise required for production.

- Taxation: It is also an essential factor in the decision-making process. This is because the rate of taxation varies across products and regions.

Besides factors, firms must review the impact of the decision considering the following constraints:

- Production Schedule

- Total Cost

- Product Quality

Make or Buy Decision Formula

Cost to Buy (CTB) = Volume × Per Unit Cost When Buying

Cost to Make (CTM) = Volume × Per Unit Direct Cost + Fixed Cost

When to Make?

Firms choose to make the product/components internally when it is more economical compared to outsourcing. Besides, it is preferred when firms want to achieve complete control over the process.

Reason to Make

The following reasons divert manufacturers toward Make decisions:

- Less cost

- Quality in process and production

- Integration with the ongoing system

- Absence of the supplier’s availability and reliability

- Optimum utilization of the available resources

- Occupying the idle production capacity

- Risk Minimization

Criteria for Make

- The cost of the finished product or service is lower than the offer price of the suppliers.

- Only a limited number of suppliers produce the demanded product. Moreover, the current supply is unable to meet the market demand.

- The manufacturing firm doesn’t compromise the quality of the product or its parts.

- The current facility for manufacturing other items is sufficient for producing the demanded product or its parts.

When to Buy?

The firms choose to purchase the product, materials or components externally when it is less costly than creating it in-house. It is preferred, especially when the firm aspires to utilize the supplier’s skills and expertise.

Reasons to Buy

The following reasons divert manufacturers toward Buy decision:

- Avail advantages of multiple sourcing

- Fewer units of products in required

- Practice reverse engineering

- Lack of skills and expertise

- Cost reduction

- Reduced exposure to risk

Criteria for Buy

- Manufacturing the product or its parts involves massive investments. Therefore, the firms prefer to procure the products from suppliers’ plants.

- The firm does not have sufficient production facilities. Besides, the firm’s capital can be utilized in other profitable sources.

- Firms can manufacture other parts efficiently with the available resources, including facilities.

- The existing human resources don’t have the required skills to manufacture the product/parts.

- Firms may face some legal issues that restrict them from producing the required product/part.

- The demand for the required product is seasonal or temporary.

Make or Buy Analysis

In order to come down to any decision, the firm analyzes outsourcing costs with total cost. If the cost involved in outsourcing is more than the total cost, then the firm must manufacture the product and vice versa.

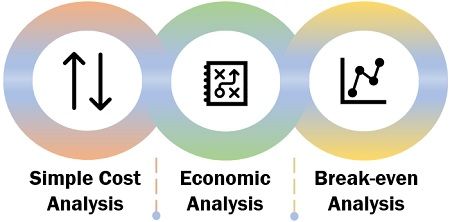

Moreover, one can use the below-mentioned techniques for the analysis.

Simple Cost Analysis

This analysis revolves around the cost of making a product or buying it. At first, we need to calculate the cost of both alternatives. After that, perform a comparative analysis and select the alternative with the minimum cost.

Economic Analysis

Here, the decision is based on the Economic Order Quantity and Total Cost. It contains two inventory models for the analysis namely:

- Purchase Model

- Manufacturing Model

Break-even Analysis

In this analysis, firms focus on Product Demand and the Break-even Point. If the quantity demanded falls below the break-even point, then the firm must go for outsourcing.

Advantages of Make or Buy Decision

Conducting a make-or-buy analysis benefits the firm in the following ways:

- Beat market competition.

- Reduction in the total cost of the finished product.

- Integration of external expertise and technology.

- Identification and fixing bottlenecks within the process.

- Cope with the fluctuating demand levels.

- Increased flexibility in production and processes.

Process

One can follow the steps given below to arrive at the best-suited outsourcing decision:

Step 1: Plan

The make-or-buy decision process begins with strategic planning at the top level. The senior management dedicates qualified personnel or forms a separate team for decision-making.

Step 2: Evaluate

Secondly, the responsible personnel go for a thorough evaluation. The evaluation involves setting goals and objectives for decision-making. In addition, personnel evaluate the exact requirement concerning market demand.

Step 3: Analyse

After that, the personnel conducts cost and benefit analysis for both the alternatives (make or buy). Also, due consideration is given to future performance and associated risks.

Step 4: Select

At last, they opt for an economically viable and profitable alternative for the firm. Also, conduct a review of the overall performance to assure their selection. Thereafter, analyze whether the selected alternative satisfies the demand or not.

Final Words

All in all, these decisions are vital from the profitability and investment point of view. Besides production, it is also relevant in fields like Accounting, Project Management, etc.

Leave a Reply